The Resanta brand is of Baltic origin – the company is registered in Latvia. The factories, which has become customary, are located in China. Welding inverters of several lines are supplied to the Russian market:

Products, according to reviews, in general, not bad, with their pros and cons. If you need a welding machine for home use, “Resanta” is quite a decent choice. As the pros say: his arc is not as heavy as other brands in the same price category. But only the quality is unstable: someone with a constant load (in shops and production) works for years, and someone every two or three weeks (also in production) takes it to repair. Only production and welders are different. And from those who operate welding inverters “Resanta” for domestic purposes – in a private home, in the countryside, in the garage – those respond positively about the work of the units.

The operating mode of welding machines of any line – 70% by 30%. Which means that when working at 140 A from 10 minutes of welding/cutting you can 7, and 3 will have to rest – wait for the machine to cool down. The ratio is not the worst and the mode, in general, convenient.

Content of the article

How to choose a welding machine “Resanta”

For household use, it makes sense to choose a unit from two lines – SAI and SAI PN.

Resanta SAI is a standard modification that works at 220 V in the network with small deviations. The range is stated as follows: +10% (up to 242 V) and -30% (from 154 V). It seems that such characteristics should be enough, but it really works normally at 190 V. If it falls even lower, problems begin and you have to put electrodes of smaller diameter.

In rural areas, the voltage is often below 190 V. With such parameters of the network can not work normally not all welding machines. If you have such a situation – you need to choose an inverter from the line SAI PN. He normally welds even at 140-160 V.

There is another line – “Compact”. It differs in even smaller dimensions and weighs a kilogram and a half less. When designating the models of this line to the number indicating the maximum welding current, the letter “K” is attributed. If weight and size are critical for you – choose a welding inverter from this line.

All others are more suitable for professional or semi-professional use. For domestic use, their “contrivances” and increased power is of no use. If you can buy them, it is not for beginners in welding.

Model selection

After the line is determined, you need to choose the maximum welding current. It is inserted in the name of each model after the abbreviation SAI. For example, SAI-160 – the maximum welding current is 160 A, SAI-220 – can deliver 220 A.

How to choose the power? Based on the work for which it is purchased, or under the size of the electrode that you prefer to work with. For example, to work with 3-millimeter electrodes suitable apparatus for 140 and 160 amperes. But the 140 will work at the limit, while the 160 will work normally. You can also consider buying a 190th, but it can already work with 4-millimeter electrodes. A power reserve is always a good thing. True, you have to pay extra for it.

More powerful models SAI 220 and 250 can work with electrodes 5 mm and 6 mm, respectively. If you do not need such power, then there is no reason to pay for them. But to choose, as always, you. Maybe you prefer to work with 3 mm electrode but with increased welding current – 190 and higher … Rarely, but there are such welders.

To make it easier to choose, in the table collected the most important characteristics of welding inverters Resanta line SAI and SAI PN, and SAI K.

Technical characteristics of welding inverters Resanta SAI and SAI PN, SAI K

| Model of welding inverter | Maximum current consumption, А |

No-load voltage, V | Arc voltage, V | Maximum electrode diameter, mm | Weight, kg | Price |

|---|---|---|---|---|---|---|

| SAI-140 | 20 | 75 | 25 | 3,2 | 4,3 | 110 $ |

| SAI-160 | 22 | 80 | 26 | 4 | 4,5 | 120 $ |

| SAI-190 | 25 | 80 | 27 | 5 | 4,7 | 155$ |

| SAI-220 | 30 | 80 | 28 | 5 | 5 | 180$ |

| SAI-250 | 35 | 80 | 29 | 6 | 5,2 | 220$ |

| SAI-60PN | 22 | 80 | 26 | 4 | 5,7 | 170$ |

| SAI-220PN | 25 | 80 | 27 | 5 | 6,4 | 200$ |

| SAI-250PN | 35 | 80 | 29 | 6 | 7,7 | 250$ |

| SAI-160K | 28,5 | 85 | 4 | 3,4 | 130$ | |

| SAI-190K | 32,5 | 80 | 5 | 4,3 | 155$ | |

| SAI-220K | 36,5 | 80 | 5 | 4,5 | 180$ | |

| SAI-250K | 42,5 | 80 | 6 | 4,6 | 210$ |

Power supply of Resanta inverters

The main plus of these welding machines is that they work from a household power supply of 220 V, without any special requirements. The main thing is that the socket was grounded. All units have protection class IP 21, which means that the device is grounded through the power cord. Therefore, to protect against electric shock, it is necessary to power the inverter from an earthed outlet.

Work normally SAI-160 on automatic machines 10-16 A, but on ten-ampere maximum welding current is not put. If you plan to work SAI 190, you will need, at a minimum, automatic machine at 16 A.

Reviews

All reviews of inverter welding machines Resanta can be conditionally divided: before 2012 and after. Before 12 years, all reviews are very good, and not from beginners, but those who use welding in professional activities. Further – worse. In 2012, the price of these machines fell significantly – almost halved. It seems good, but, as it turned out, the quality also significantly decreased. After this date, there are different reviews, although positive still prevail.

In our shop Resanta 250 (SAI), a year worked every day, until someone attached her legs. There were no complaints about the work, only the cables are short. So we bought a new one. After 3 months this one just stopped welding at one point. The service did not ask questions, just repaired and that’s all. Now everything is normal, we work in a mature way. Except for the cables, no complaints.

Vitaly, Kineshma, 2013g.

I am a technologist, and on me the purchase of tools. Needed an inverter for welders – worked with a transformer, so decided not to buy yet expensive, in case it does not go at them, so I bought “Resanta SAI 250”. For two years of hard work, not a single problem. Transformer now stands, and this one is always busy. Boil on it and specialists, and those who have only seen how to work normally need to work. Nothing, it works. They say that with “Resanta” – a lottery. We seem to have drawn a good ticket. Only replaced the welded cables – put 10-meter section of 25 mm2: the previous five-meter were inconvenient.

Nikolay, St. Petersburg

Repaired for the fourth time … “Resanta 220” at my place. All previous repairs were enough for two weeks of work. Last time repaired by blat (got to the point) in another service. They put, as they said, a normal board. Worked for a month, so far so good. I used to sin on the quality of the device, now I’m at a loss, maybe the service is like this? They put crappy parts so that I pay them? I’m angry.

Grigorievich, Volgograd

I have “Resanta 190”. I work it periodically for three years. Everything is fine, you just need to turn on and off, as prescribed in the manual, to set the minimum welding current. It is not difficult for me, and I do it. I also periodically clean the dust. It is critical for such machines.

Vitaly Sergeyevich, Sergiev Posad.

I have already three years working “Resanta 220”. Exactly works. For all this time changed only coolers. But I clean it regularly, I try not to cut it, I do not give it into the wrong hands. Near the welding do not work with a bolgar or grinder – there is a lot of dust from them, and for inverters it is very harmful. If it is necessary to work with a bolgar, I take out “Resanta”. If all this is a burden to you, look for another machine. There are Europeans, they are not so demanding to working conditions, but they cost several times more expensive, and even with our dancing voltage do not want to work. So, if you need a European, working in our conditions, buy a stabilizer. That’s how it is.

Anatoly, MO

“Resanta” is not a welding machine, but a bunch of g….a. I’m tired of carrying it for repairs. It breaks down all the time. It just stops welding, that’s all. I will take another one.

Alexander

I bought “Resanta SAI 190” in May 2014. In November it caught up. In the warranty shop said that a lot of metal dust, that’s why it burned. Wanted to reduce to non-warranty repair (at my expense), but after a dispute repaired under warranty. Now I keep it safe. But how it will work further – I do not know.

Vlad, Kirovograd

As you can see, positive reviews about “Resanta SAI” prevail, although there are some negatives. From the experience of operation, you can draw some conclusions about how to make welding work without problems.

Operation of welding inverters Resanta

In the instruction manual for these welding machines, the requirements and recommendations are as follows:

- Do not use near the unit a Bulgarian, electric saws, grinding and other tools, when working with which there is a large amount of dust.

- Do not cover the body during operation: forced cooling – coolers (fans). If you close the air supply, the machine will overheat and may burn out.

- Do not work in wet rooms or in the rain.

- If you bring the inverter into a warm room from frost, it is necessary to wait at least two hours until the condensate dries.

Switch-on procedure

Before turning on the unit, check that the switch is in the off position. Connect the power cable and workers, plug into the socket. Set the minimum welding current on the regulator, then press the “on” button. Switching off is carried out in the following way: first unscrew to the minimum, then switch off with a toggle switch, and then from the mains. If the work is finished, disconnect the wires and put them in place.

When unrolling the cables or using an extension cord, make sure that all wires are unrolled completely and do not cross each other. Do not leave cables coiled: this creates a coil of inductance that negatively affects the equipment.

Practical recommendations

In inverters Resanta SAI stands protection against overheating. It automatically disconnects the device when the temperature approaches a critical temperature. But it is better not to bring it to shutdown. Work in intermittent mode: 7 minutes you cook, 3-5 minutes you give the unit to cool down. It is not necessary to turn it off for these intervals.

There is no need to turn off the power and when the unit shuts down due to overheating. Just wait for 5-7 minutes. Do not switch off even if you have a short break in your work: the less frequently the equipment is switched on, the longer it will last. Inrush currents, although there is a “soft start” function, have a bad effect on this kind of equipment. Therefore, turn off the inverter only if the break will be more than an hour.

If you want Resanta SAI to work normally, periodically clean the insides from dust. Especially if you worked near the source of dust or after a long downtime.

Weld stainless steel Resanta need to reverse polarity.

If you are going to extend the working cables, increase their diameter, less voltage sagging. If you put on 10 meters – cross-section is desirable 25mm2.

Practical tips for repairing Resanta welders

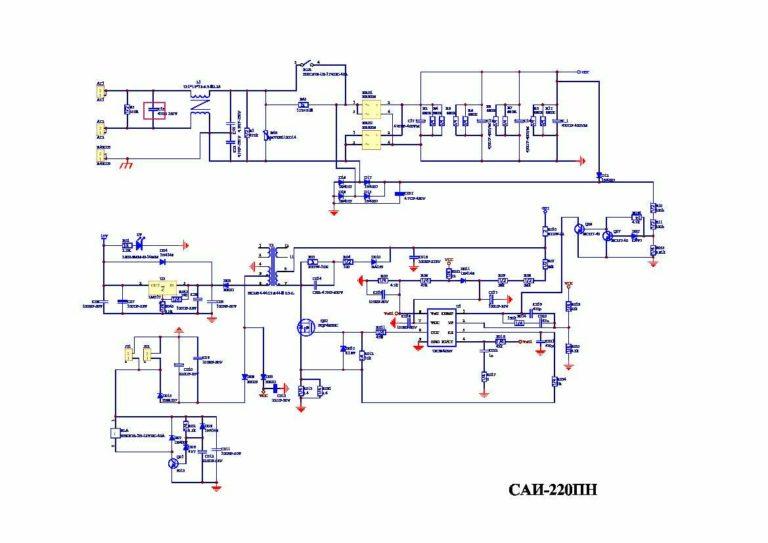

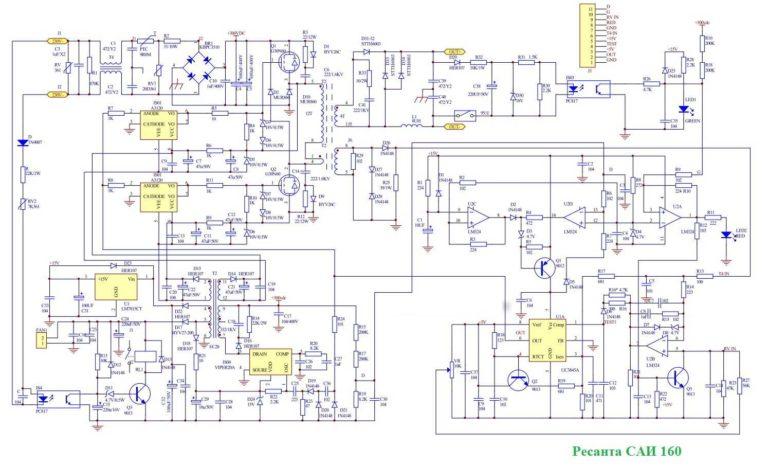

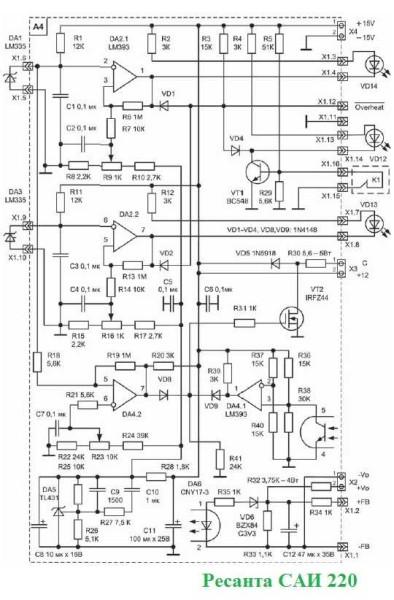

If you have the skill of such works, then the schemes posted below will help you. There are also a few recommendations based on the experience of “self-made”.

After a year and a half of work Resanta 220 began to shut down on overheating if you work at currents greater than 140 A. The warranty was over, so I went to look myself. All in all it was that the input cable was badly drawn. By the way, it was worn out – worked every day for a year and a half. I replaced the cable, tightened the terminals in a feminine way, and vacuumed it.

Timofey, Primorsky Krai

I bought myself a Resanta 250 Prof. The seam holds perfectly, cooks softly. I like it. Except that after a month of work (1 kg of triplets a day, but not always, there were less), after the cotton inside it died. Gave it to repair, waited 45 days. After repair a month later there was a breakdown. It happens if the electric wire is not clamped in the holder. I didn’t want to wait another 45 days, so I unscrewed it myself. There were almost no wires screwed to the board. They were just crimped on. How did the service people look at it? Or did they do it on purpose? A piece of the board burned out. I soldered the wire to the terminal, screwed it back on. It works. True at subzero temperatures now the indicator shows something inconceivable, but it works.

Vitaly, Krasnodar

My Resanta SAI 220 after a month of work triple stopped giving signs of life. I opened, checked, two transistors FGH40N60SFD burned out. I found them, bought them, changed all four, although two were burned out. I also replaced the 12W resistor with a 51 ohm resistor. It worked, but not for long. The transistors burned after a few turns on. Apparently, the batch was defective. I bought other ones, put them in and it works fine. Yes. To my 220 was more suitable scheme from 250 – with minor inconsistencies. What can I say, the board is made normally, the tracks are not peeled off. At least that’s good. Although they could have tested the parts before putting them into production.

Anatoly, Nizhny

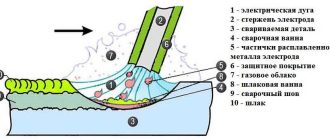

Masks for welding Resanta

It is impossible to work with welding without a welder’s mask – immediately get a retinal burn, which is called “bunny”. Light filters protect your eyes from infrared and ultraviolet radiation damage. The mask housing protects against flying spatter and dross. Both should be reliable and provide maximum protection.

Resanta produces several types of welding masks:

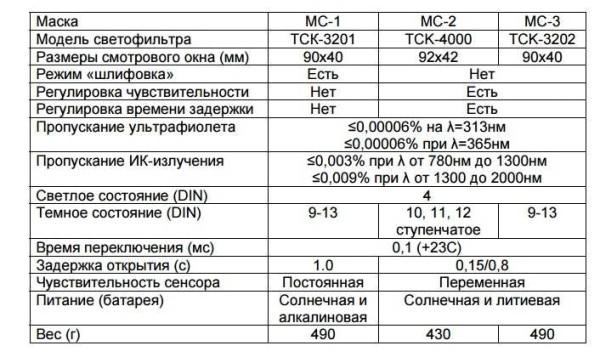

- MS-1 – with an automatic light filter on liquid crystals TSC-3201. There are two modes: welding and grinding, dimming regulator, which allow you to use the mask both for welding and as a protective shield when working with a bolgar or other similar tools. Price 1500-1800 rubles.

- MS-2 – with a light filter TCK-4000. Adjustments are three: the degree of dimming, sensitivity, delay time (how quickly triggers when changing the brightness of light). Step change in dimming. Price 1900-2100 rubles.

- MS-3 – light filter TCK-3202, adjustments are the same as in MS-2, but the change in transparency of the light filter is smooth. Also different range of adjustment at Resanta MS-3 – 9-13DIN, at Resanta MS-2 it is 10-12DIN. Price 2600-2800 rubles.

- MS-4 – the cheapest (price 1200-1400 rubles) and the simplest mask. Light filter TSC-2101. Works only at positive temperatures, even at a slight decrease begins to “slow down”.

All the main technical characteristics of Resanta MS welder’s masks are given in the table.

And a video review of the Resanta MS-1 welding mask.

Several schemes of welding inverters: