Welding is a great way to join metals, but it is not always convenient or possible. The alternative is riveting. But to install rivets, you need to choose a riveter. How to do this read on.

Obsah článku

What is a riveter and how it works

Riveters or riveters are devices for installing rivets. There are special tools for different types of fasteners. There are separate ones for pulling, screw rivets. There are also universal models, but they belong to the group of professional tools, respectively, cost solid.

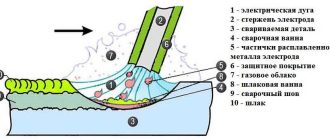

To choose the riveting tool correctly, it is desirable to understand how it works. Regardless of the type of rivets with which the unit works, the principle of riveting is always the same: the device flattens the second (far) part of the rivet, forming a closing head. Only the method of flattening can differ:

- When installing pull rivets, the jaws grasp and pull the rod. At the end of the rod there is a ball that rests on the edge of the rivet body and crumples it. When a certain amount of force is reached, the rod breaks off.

Riveter operation when installing pull rivets - The installation of screw rivets is different. Inside the hollow body, a thread is applied. A screw of a suitable diameter is screwed into this hardware. When screwed in, it begins to pull up the edge of the rivet, due to which the plastic metal is flattened (see video below).

- Hollow rivets (pistol rivets) are simply flared with a cone-shaped nozzle. Piston rivets are used in non-loaded areas, but more often not in construction, but for finishing or when joining parts made of leather, fabric, etc.

Piston rivets are the easiest to install, but they have the lowest reliability. They are used infrequently in construction, except for handicrafts

In general, the process is clear. As you can see, the only difference is that in one case it is necessary to pull the rod, in another – to twist the screw, in the third – the cone nozzle is pressed. When choosing the type of rivets, pay attention to the fact that the tool for pulling is inexpensive, but for screw rivets usually costs a lot. This is mainly limited to the use of screw rivets. Well, and the fact that they are hollow – not airtight.

Selecting the drive type

Before choosing a riveter, you need to understand what they are. Let’s start with the drive.

Video review of the MILWAUKEE 2550-20 M12 RIVET TOOL cordless riveter.

For household use, you buy manual riveting tools. But even this “simple” tool is not easy to choose. First of all, the price range is surprising – from 5$ to several hundred dollars. How to orient yourself here? Let’s say right away that too expensive to take for one-time use is definitely not worth it, as well as too cheap. In the rest it is necessary to understand.

Types of manual (mechanical) riveters

There are three types of manual rivet installers:

- one-handed;

- two-handed;

- accordion.

One-handed are designed for fasteners of small size – up to 5 mm. They differ in that their working handles are at an angle of 90° to the installation axis. That is, the handles are directed downward. It is convenient because you can work with one hand. The disadvantage is a small “range” of sizes with which the device can work.

Two-handed are characterized by large sizes, they can be installed and rivets of large diameters – up to 8 mm. It can be distinguished by its appearance – long handles that are in the same plane with the working jaws. It makes sense to choose a two-handed riveter if you plan to use rivets with a large diameter.

Mechanical riveters “accordion” are more often used with fasteners of large sizes. The presence of the same “accordion” allow you to install large-sized fasteners with less effort. Such a device usually has a more expensive tool, it is more often used by professionals.

Choosing the type of manual riveting machine is not too difficult. If you need a reliable machine, choose from two-handed models. Their device is simpler, there is almost nothing to break. With normal quality, they are unbreakable. If you will put only small fasteners – no more than 2-3 mm, it is advisable to take a one-handed. It is more convenient to work with them.

Criteria for selecting manual rivet installers

So, if you need to choose a rivet setter of manual type, pay attention to the following parameters:

What else pay attention to is the handles. The rubber pads on them should be made of good rubber. The handles themselves should be comfortable for you, so you can work faster and longer. Also pay attention to the possibility of fixing the handles when not in use – there is a special wire loop that holds the handles together. When storing it is convenient and important.

Choosing a rivet extractor

Most often it is necessary to work withdrawing (pulling) rivets. They are convenient, inexpensive. The tool for their installation does not cost too much. In addition to the above parameters, in order to choose a riveter for pull rivets, you should also pay attention to some special characteristics and options.

Now you know how to choose a rivet driver for pull rivets. After selecting a few models that suit your needs, inspect them and hold them in your hands. If possible, try a couple of times in the work. This way it will be easier to understand which tool is more comfortable for you to work with and it will be easier to make a choice.

Drill/driver attachment and the specifics of selection

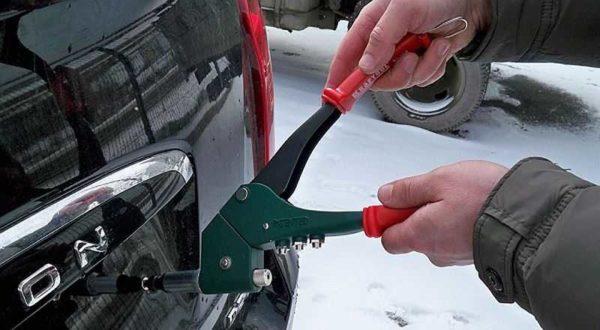

With a large front of work with the use of manual riveters, hands get very tired. Of course, there are cordless, but the price for them does not please at all. And if you also use them only occasionally, it is not reasonable to buy an electric tool. In this case, you can compromise – to buy an attachment to a drill or screwdriver for installing rivets.

This is a small adapter (nozzle), which is inserted into the chuck. There are them for screw and extractor rivets. If desired, you can also find under other types of fasteners.

The principle of operation of the drill with an attachment for rivets is not different – the same tool pulls the pin, then breaks it off. Except that the broken “tails” must be taken out by yourself, switching the drill to reverse. In the case of using screw rivets, reverse is also required – to remove the nozzle from the installed fastener.

The choice of riveting nozzles on the drill is similar: by type, size and material of the nozzle. Well, and the shank should fit the chuck of the power tool. Also pay attention to the presence of a handle. This is a non-critical parameter, but increases the convenience of use. Drill with a screwed-on nozzle is heavy and unstable. Therefore, when working, it is necessary to hold the nozzle with your hand, fixing its position. To avoid holding on to the nozzle, a handle is put on. In this version, it is more convenient to use the machine and the position can be controlled more accurately.

How to choose a riveting tool: manufacturers and prices

When choosing a particular model, many people rely on prices. Except that the spread is very large – there are very cheap and, almost the same in appearance, but many times more expensive. Even dozens of times more expensive. Immediately it is worth saying that even for one-time work, buy a very cheap rivet – too risky. It may not work at all or may work through a stump.

If you only want to rivet a fence, for example, even in this case you will have to install more than one hundred rivets. If you have to disassemble the tool after every 2-3 rivets, you will definitely not like it. To choose a riveter that works well, pay attention to the middle price range.

If you intend to use the riveter in professional activities, you should choose a more expensive one. Firm – at your discretion, but from the category of professional or semi-professional models. Perhaps they do not differ structurally, but have a greater resource, service life. That is, they are made more reliably and qualitatively. And this explains the difference in price – more expensive/quality materials are used.