Wood or coal is not available everywhere, but wood and agricultural waste can be found probably everywhere. It has long been noticed that they burn, maybe a little worse, but you can heat with them quite well. But just pouring sawdust or straw is very inconvenient. That is why it was invented to process them and press them into briquettes or pellets. For fuel pellets – pellets – there are even special boilers. If the fuel is good, they are serviced (rake out the ash) once a month. The best news is that it is quite possible to make pellets with your own hands. This will require quite a lot of equipment, but the basis is a pelletizer (extruder or pelletizer). Without it there is no way.

Contents of the article

What are pellets and what kinds of pellets they are

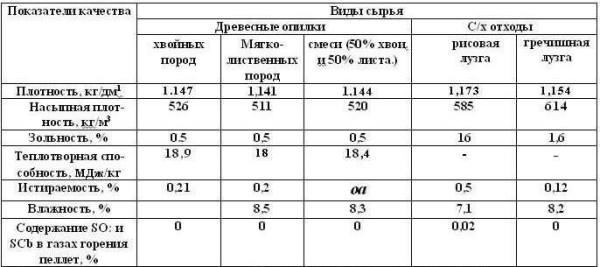

Pellets are fuel pellets, which are made from woodworking waste, some crop residues (straw, sunflower husk, buckwheat, etc.) and even from chicken droppings. The technology of their production is such that no additives and binders are required. That is, it is absolutely safe and 100% natural fuel, which is also made from waste.

Since the raw material for fuel pellets can be different, then the characteristics of the fuel are different. Pellets are divided into three categories:

- White. This is a premium class fuel with the highest characteristics (and price). It is named so for its characteristic color – light yellow, almost white. But the color is secondary, the primary characteristics and the main one is very low ash content. After combustion of white pellets ash remains no more than 0.5% of the fuel volume. It will be necessary to clean the boiler very rarely. White fuel pellets are produced from shavings without bark and other foreign inclusions. As a rule, this is carpentry or furniture production.

- Gray. Raw material for this type of pellets may contain a certain percentage of bark, needles and some other extraneous impurities. But the ash content should not be more than 1.5%.

- Industrial or dark pellets. This type of fuel pellets is made from straw or cake in pure form or with the addition of wood waste. The ash content of this type of fuel is much higher than those described above, nevertheless, it can not be higher than 5%.

White and gray pellets are used for individual heating. They are also called “first class” or pervokassnye. They have a diameter of 6-8 mm, a density of about 600 kg/m3, the amount of heat released – about 4.7 kWh. They are burned in special boilers, which are so called – pellet boilers. Usually this equipment is very demanding to the quality of fuel. In addition to low ash content, there are also requirements for the integrity of pellets, and the absence of dust-like fraction. Otherwise, the burner of the pellet boiler clogs, the boiler shuts down. Industrial pellets are also burned in special furnaces, but they have a completely different structure and much larger volumes.

In principle, any pellets can be poured into solid fuel boilers, only they are usually used at the smoldering stage. When the furnace is already heated up, pour a certain amount of pellets.

Production technology

For any owner, the idea of turning waste into fuel, or even make money on it, is attractive. In principle, it is realistic to make pellets with your own hands, but you should not expect industrial quality from them. To make an imported pellet boiler work on homemade pellets is unlikely to work, but a homemade or solid fuel unit copes with them perfectly.

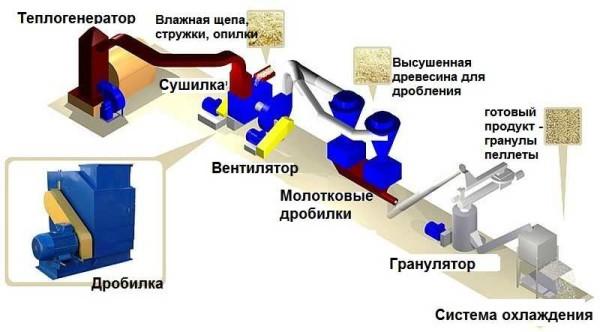

The technology of production of wood pellets consists of several consecutive stages:

- Coarse crushing of raw materials. Fragments should be no more than 1.25 cm3. This is a preparation for better drying. For this operation, a crusher is needed.

- Drying in the drying chamber. Raw materials are brought to a moisture content of 8-12%. There are different types of chambers, some use direct heating (in the drying chamber heated air is supplied from the furnace), in others the heat exchanger is heated, and from it – the air in the dryer. The second option is less efficient, but in this case there is no possibility of soot getting into the raw material. Even a small amount of soot can color the wood chips. As a result, the quality of pellets can refer to “white” (if the appropriate raw materials were used), and the color – to gray.

- Fine crushing. The dried wood is fed into crushers (usually of hammer type). At the output, wood fragments have sizes of more than 1.5 mm for white and gray pellets, and 4 mm for industrial pellets.

- Moisturization. Wood fibers with low humidity will not be able to glue. Therefore, they are moistened. If pine, spruce waste is used, water is injected. Raw materials from hardwoods – oak, birch, beech – are treated with hot steam.

- Pressing. Presses of different designs are used here. Raw materials are pressed through a matrix (flat or round), which form cylinders of specified dimensions.

- Cooling. Under the influence of high pressure pellets are heated to 70-90°C. In this state they crumble easily, so they are left to cool down.

- Finished pellets are sieved (from residual unglued particles) and packed.

As you can see, the process is multi-stage and requires quite a lot of equipment. Nevertheless, in the presence of cheap or free raw materials, it is profitable to produce pellets with your own hands.

Features of the production of pellets from straw

To make pellets from straw is easier. It initially goes dry, so there is no drying stage. If there is wet straw, it is dried in natural conditions in the sun, and then crushed and mixed with dry, thus achieving the required moisture content of the raw material before pressing.

Chopping is also easier. This requires a straw cutter, which immediately cuts the raw material into fragments of the required length. So the chopping also takes place in one go. After bringing the mass to the required moisture content, it is pressed through the press. And here everything is simpler: since the raw material is softer, less effort is required. Less powerful equipment means lower costs. At the same time, the productivity of the line can be high.

As you can see, the equipment for the production of pellets from straw is required less, and the time and energy costs are also less.

Homemade pelletizers

Although the equipment for the production of pellets requires a lot, the main device is a pelletizer. With its help, pellets are formed from raw materials. There are several models of pelletizers:

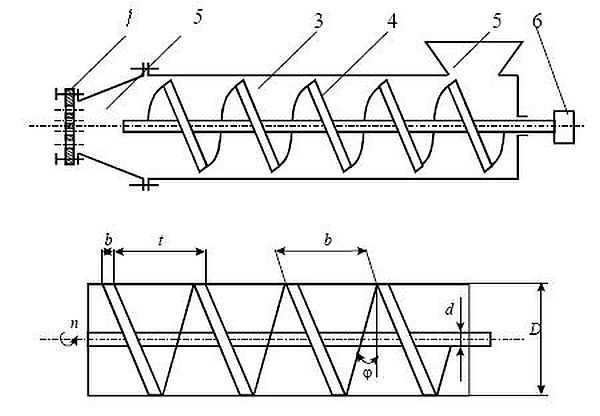

- Screw. In structure, they are similar to a household meat grinder. The same screw shaft and matrix – a grid through which the raw material is pressed. They can be used for soft raw materials, for example, straw. Wood, even well chopped, it “does not pull” – not enough force. In principle, if the parts are strong enough, you can put a more powerful motor.

- With a flat die. There is a metal circle in which holes of the required diameter (usually 3-4 mm) are made. There are toothed rollers that push the raw material through the holes, forming pellets.

- With a round matrix. The idea is the same, only the matrix is made in the form of a ring, respectively, the rollers are located in a different plane. This option has a large capacity, but granulators of this type are rarely made with their own hands.

The simplest in structure is a screw extruder. It is often made for pressing mixed fodder, but it can also be used for making fuel pellets from soft raw materials. If you need to make equipment for the production of pellets, this is the easiest option. Provided that you know how to handle a lathe and a welding machine.

Homemade screw pelletizer

As in any equipment of this type, the screw pelletizer has a matrix. In this case, it is similar to the mesh of a meat grinder, only made of a plate much thicker. The second important node is the screw shaft. All these parts can be made with your own hands. How – it is useless to describe in words, look in the video.

Making a matrix for the finished screw.

Screw and matrix are “packed” in a case or a sleeve. How to make it, see in the following video.

After assembling the main unit, it is necessary to install a motor with a gearbox, a hopper, into which the chopped straw will be fed. You can start.

How to make a granulator with a flat matrix

First you need to understand how it is arranged. Everything is perfectly demonstrated in the video.

In the following video, quite detailed explanations on the process of making the matrix and rollers.